- Expert Since 2013

- +918347947404

- ashaenterprise123@gmail.com

CLEAN AGENT TUBING SYSTEM

ASHA AUTOMATIC CLEAN AGENT TUBING SYSTEM

Description

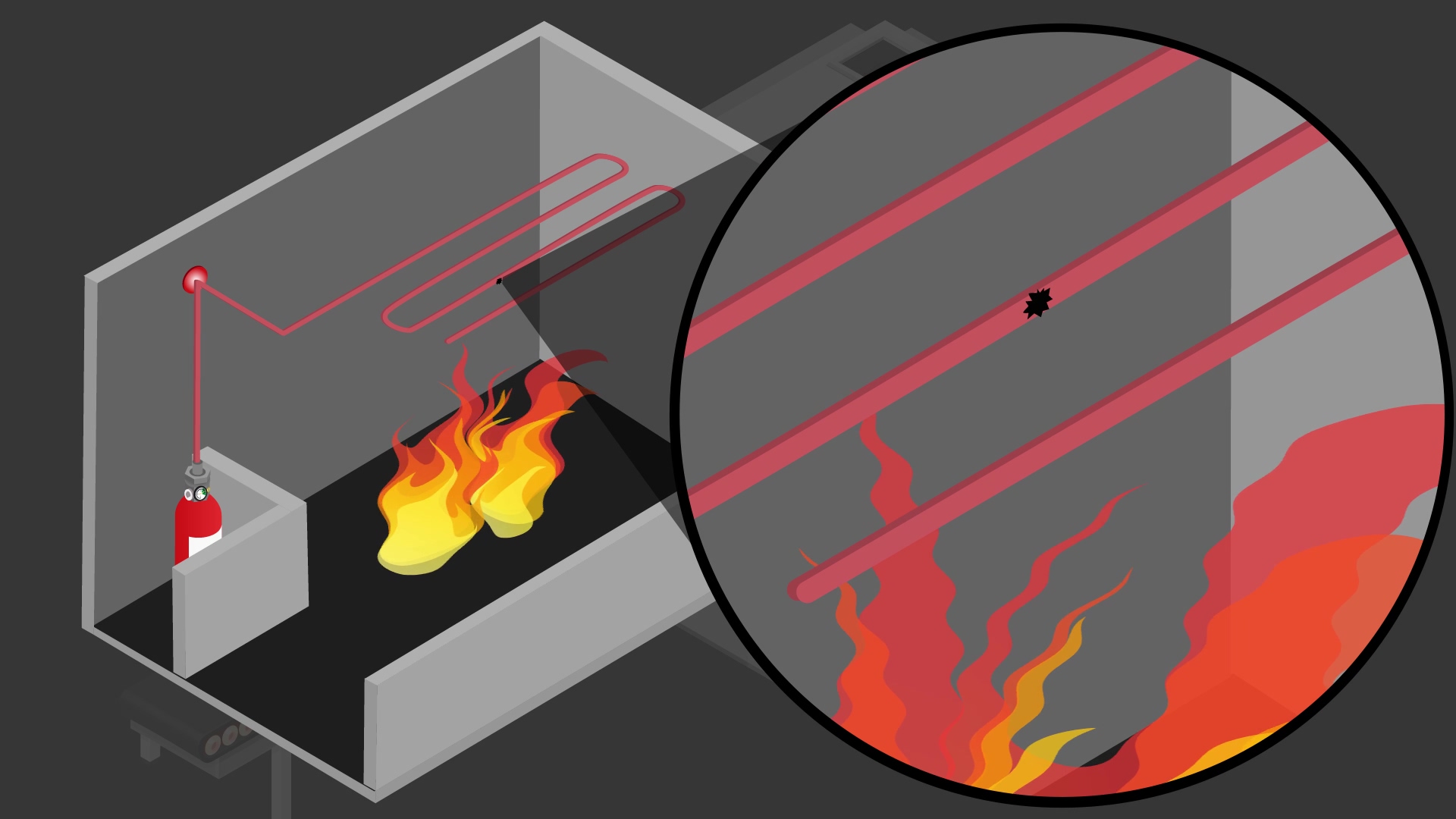

We are pleased to introduce ASHA ENTERPRISE Automatic Clean Agent Tubing System is an innovative automatic fire suppression system designed to provide a fast and reliable solution to extinguish panel & cabinet fires and help protect electrical panels. With the modern dependency on systems required being live, any interruptions in operations can involve huge financial costs and impact businesses severely. Therefore it is essential that special attention is paid to effective fire protection for these electrical installations ensuring you can achieve ideal protection for your equipments.

ASHA ENT Automatic Clean Agent Tubing System provides ideal protection ensuring the fire will be extinguished in the first critical moments of their occurrence works fully independently. The system is connected to a monitoring panel which provides necessary indication upon operation of the system and can be connected with the existing BMS / SCADA panels to ensure proper monitoring of the systems.

The system uses clean and green UL Listed, globally recognized non-toxic fire extinguishing agent

(FM200/HFC227ea), (FE36/HFC236fa) and (Novec1230 / FK-5-1-12) to provide quick and reliable

suppression to combat the fire and suppress it before it can spread within the cabinets

minimizing potential fire damage. The system is manufactured in two versions when used with

Clean Agents:

1. ASHA Direct Low Pressure System

2. ASHA Indirect Low Pressure System

This system is referred to as direct, which means that the activation and distribution of the clean agent (HFC227ea,HFC236fa & FK-5-1-12) is secured by the detection tube.

The fire suppression system operates by detecting fire and applying the agent using a detection tube connected to the cylinder valve. The detection tube is placed in the protected enclosure and is under constant pressure. In case of fire the detection tube degrades by the effect of fire or high temperature. When the detection tube is disrupted, the agent is released through the created hole. The detection system is independent of any electrical supply and operates.

This system is referred to as indirect, which means that it is activated by disruption of the detection tube and the agent is distributed via separate distribution tubes to the nozzles.

The fire suppression system operates by detecting heat with a detection tube connected to the valve of the cylinder. The tube is placed in the protected enclosure and is under constant pressure, whereby keeping the valve piston of the cylinder closed.

The indirect system is suitable for larger environments or where specific application of the agent is required. This system also enables various modifications by adding optional components such as manual actuation, control panels for enhanced operation and control of the system.

CLEAN AGENT FIRE SUPPRESSION

Description

HFCs /FK-5-1-12 are pure gases that leave no residues, they have minimal environmental impactd and having no depleting effect on the ozone layer. HFC227ea and FK-5-1-12 ore over-pressurized with nitrogen to 25/42 bar.

The HFC gases and FK-5-1-12 are dielectric, clean and safe for humans and delicate equipment and precious objects. HFCs extinguish ires partly by physical means by Subtracting thermal energy from theire, and partly by chemical action, releasing into the space small quantities of wines on release tree radicals and inhibit the combustion chain reaction.

The integrity of any volume protected by a total looding system must be checked to locate and seal any signiicant air leaks. Leaks can result in failure to maintain the concentration level of the extinguishing agent for the speciied period of time. Verication of leaks must be conducted via the "Door Fan Test."

ADVANTAGES

Low cylinder instollation space requirement

Suitable for protection of occupied areas

Fast extinguishment thanks to rapid

Low installation and maintenance costs

Extinguishing agent discharge

Does Not Conduct Electricity

Leaves No Residues After Discharge

No Potential For Ozone Layer Depletion

Low Global Warming Potential

DISCHARGE TIME

The HFC/FK-5-1-12 extinguishing system is designed - using dedicated software for calculating the cross- section diameters of the nozzle passages to discharge the extinguishing gas into the environment in 10 seconds. Discharge time is defined as the time needed to reach 95% of minimum design concentration.

Full discharge within 10 seconds is clearly advantageous with respect to technologies that provide discharge times and consequently, extinguishment times in excess of one minute. Use of the HFC/FK-5-1-12 extinguishing agents guarantee fast fire suppression and therefore less damage both to the protected spaces and objects and people present in the areas.

CERTIFICATION

The system cylinders conform to DOT/BIS/PESO standards. The components meet the requirements of the TPED 2010/35/UE, of the Construction Products Directive (CPD-89/106/CE), and of the EN 12094-series standards and are VdS approved. The clean agent FITECH227 (HF0227ea) is UL recognized

REFERENCE STANDARDS

System design conform to various international standards, indudings

- NFPA 2001 Standard on Clean Agents Fire Extinguishing Systems

- VdS 2381 Fire Extinguishing Systems Using Holocarbon Goses

| |

||||

|---|---|---|---|---|

| Art Gallery Museum Archive | Computer | Control Room | Record & Storage Facilities | Petrochemical Installation |

| Pharmaceutical & Medical Facilities | Flammable Liquids | Areas Normally Occupied By Personnel | Engine Rooms On Ships | Electronics & Data Processing Warehouses |