- Expert Since 2013

- +918347947404

- ashaenterprise123@gmail.com

Aerosol

ABOUT FIREPRO

FirePro came to prominence in the fire fighting industry, following the 1994 Montreal Protocol on ozone depleting substances that banned the use of Halon 1301 fire extinguishing agent - the universally accepted and most widely used at the time.

FirePro Systems Ltd established in 1996 |

HQ & Manufacturing Facilities in Cyprus |

Distributors in >80 countries |

Installations in >110 countries |

DISTRIBUTION NETWORK

Albania |

Belgium |

Bulgaria |

Croatia |

Cyprus |

Czech Rep. |

Denmark |

Estonia |

Finland |

France |

Greece |

Greenland |

Hungary |

Iceland |

Ireland |

Italy |

Kosovo |

Luxembourg |

Malta |

Netherlands |

Norway |

Poland |

Portugal |

Romania |

Serbia |

Spain |

Sweden |

Switzerland |

Turkey |

United Kingdom |

Argentina |

Brazil |

Canada |

Chile |

Colombia Ecuador |

Mexico |

Panama |

Peru |

Uruguay |

U.S.A. |

Bahrain |

Iran |

Iraq |

Jordan |

Saudi Arabia |

Lebanon |

Oman |

Qatar |

Syria |

UAE |

India |

Australia |

Bangladesh |

Georgia |

Hong Kong |

Indonesia |

Macau |

Malaysia |

New Zealand Papua |

New Guinea |

Philippines |

Singapore |

South Korea |

Taiwan |

Thailand |

Vietnam |

Angola |

Egypt |

Kenya |

Morocco |

Nigeria |

South Africa |

Sudan |

Tunisia |

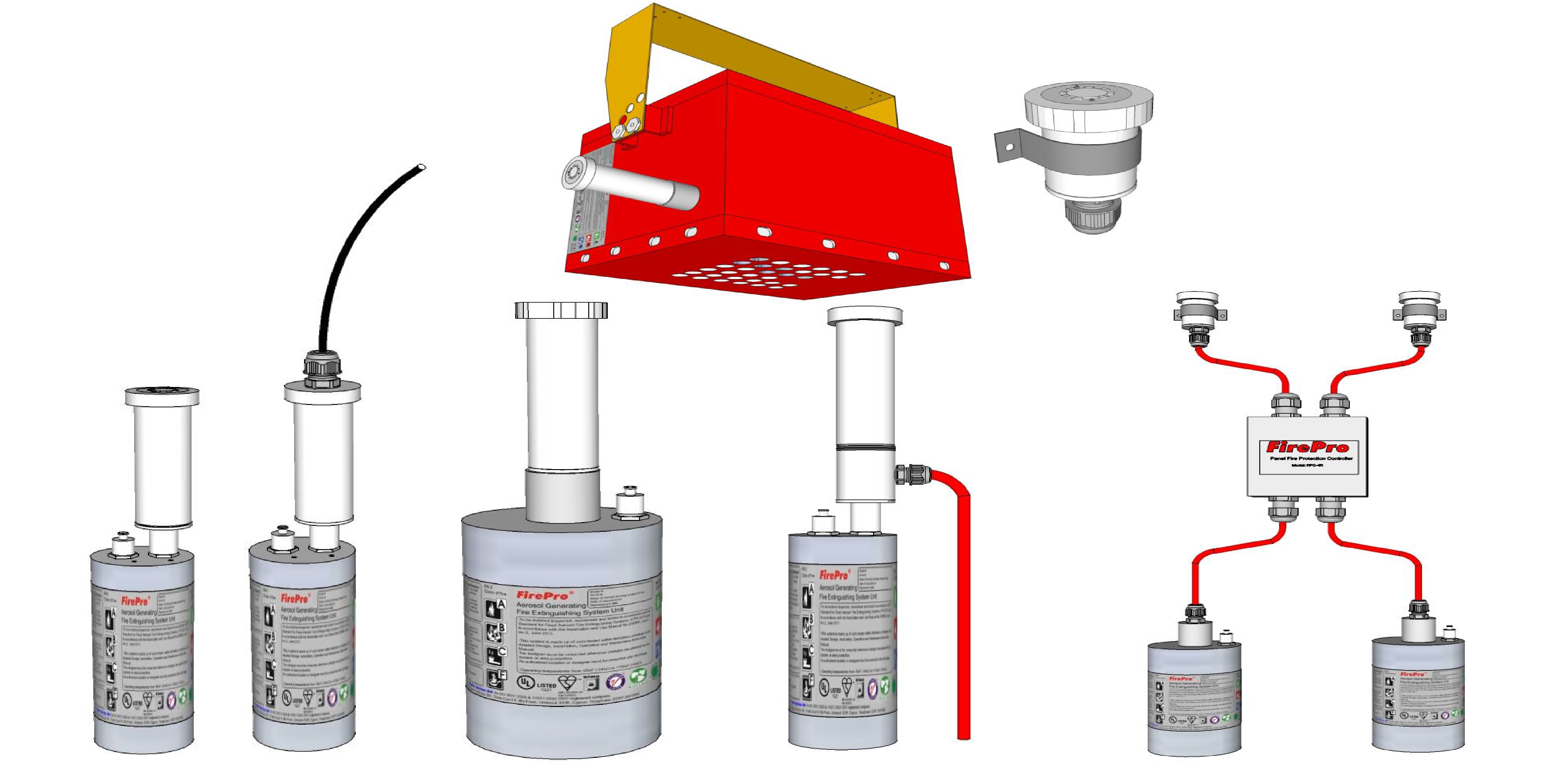

RANGE OF PRODUCTS

What is Aerosol?

Colloids: Particles with diameter of a few microns – nanometers

HOW DOES AEROSOL WORK?

Step

01

KOH react with CO2 to form Potassium Carbonate

Step

02

Formation of Potassium free radicals

Step

03

K+ (radicals) react with fire free radicals

(OH, O, H)

Step

04

Formation of Potassium Hydroxide

Patented Technology FPC Compound

at 300C |

cooling materia |

Health and Safety Features

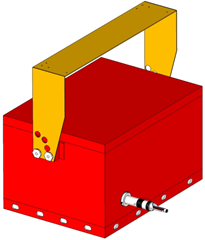

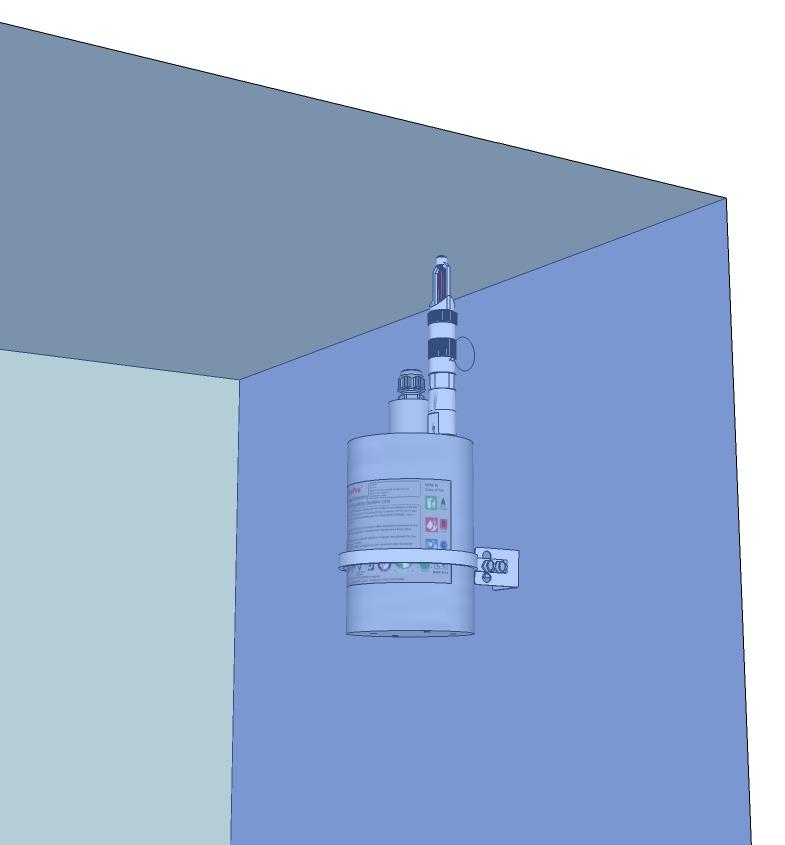

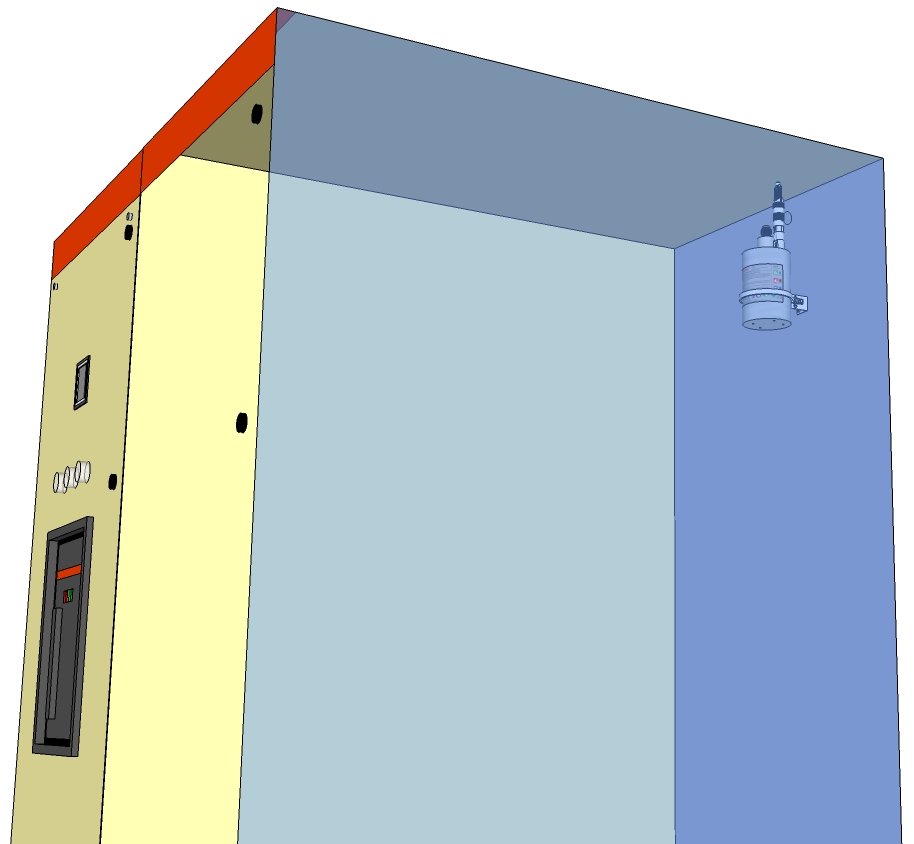

CONDENSED AEROSOL GENERATOR

EFFICIENCY

4x more efficient than Halon 1301

6x more efficient than FM-200

7.5x more efficient than FE-13

15.5x more efficient than CO2

40x more efficient than inert gases

PAIN Points

- Storage

- Pipes

- Pressure

- Room Integrity

- Maintenance

- Installation Time

- Retrofitting etc.

GAIN Points

- No Storage

- No Pipes

- No Pressure

- No Room Integrity

- Minor Maintenance

- Less Installation Time

- Easy Retrofitting etc.

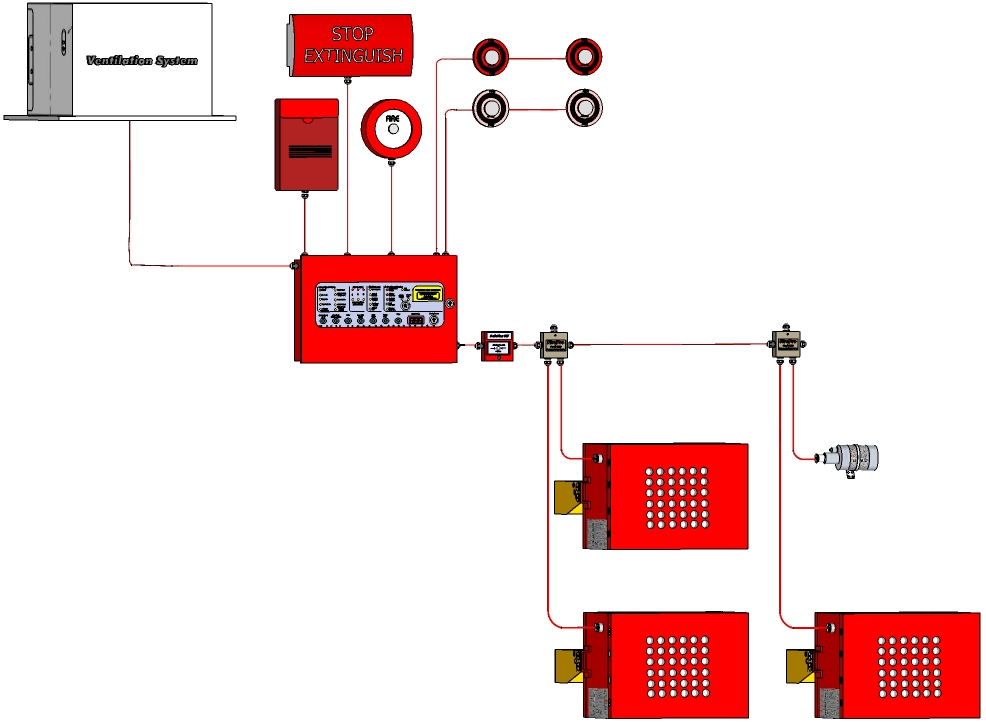

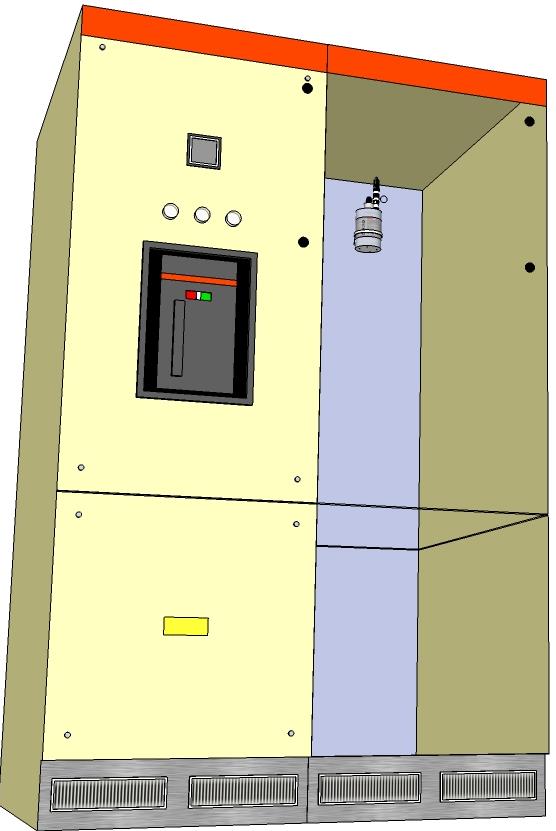

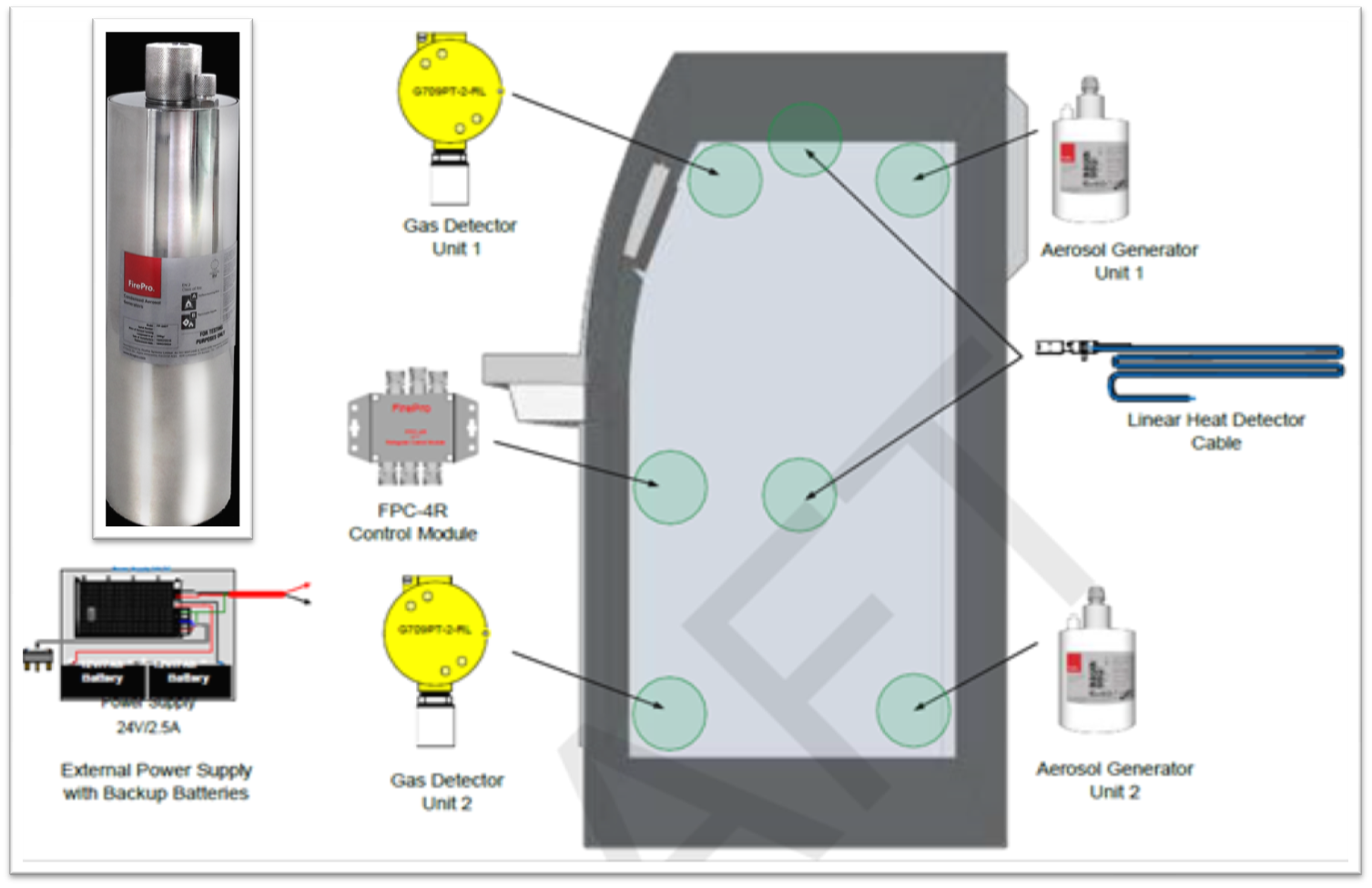

Designing an extinguishing system With Aerosol Generators

Part List

| 1 | Extinguishing Panel |

| 2 | 1st Stage Sounder |

| 3 | 2nd Stage Sounder& Strobe |

| 4 | Extinguishing Indication |

| 5 | Zone 1, Smoke Detectors |

| 6 | Zone 2, Heat Detectors |

| 7 | Isolation / Abort Button |

| 8 | Sequential Activators |

| 9 | Aerosol Generators |

| 10 | Air dumpers |

| 11 | Gas Release Sign |

| 12 | Fire Pro Unit |

| 13 | Manual Release Button |

| 14 | Connection Port To Shut Off Extractor Fan Or Close Fire Dampers |

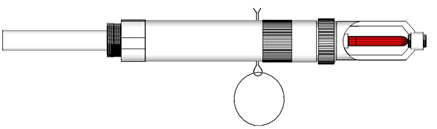

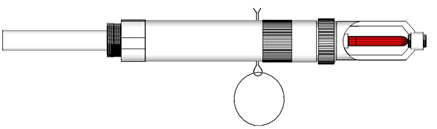

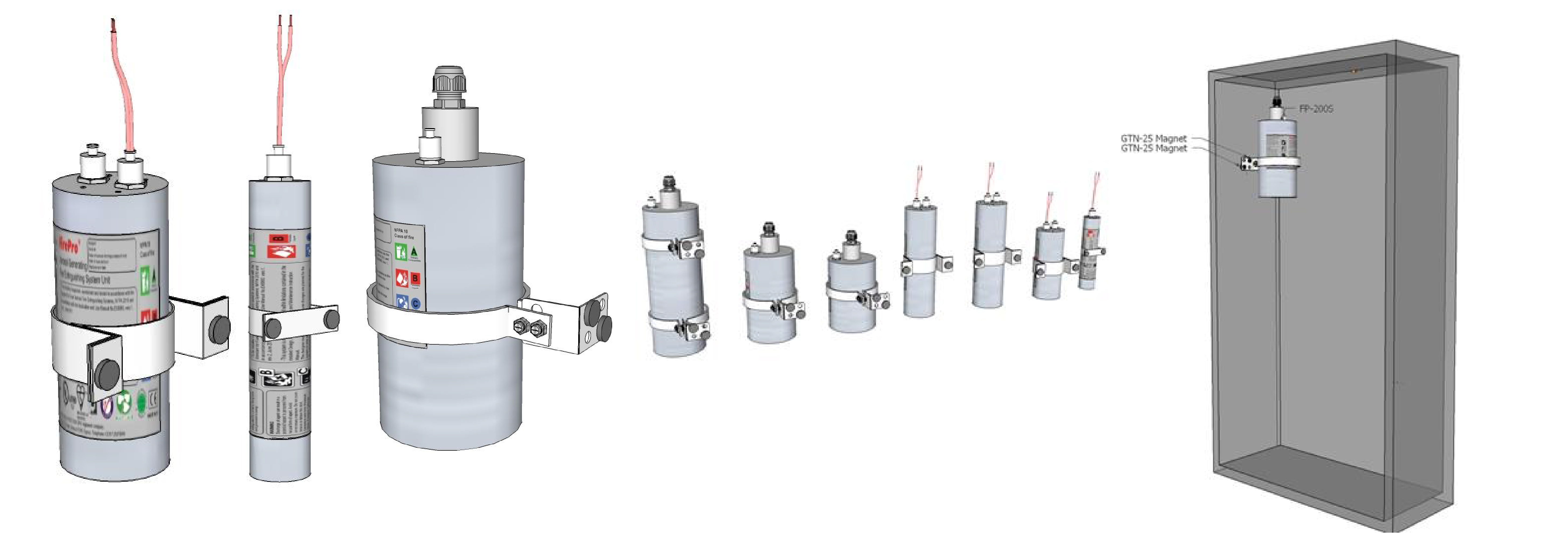

Bulb Thermal Actuator

FirePro Aerosol Generator with Bulb Thermal Actuator (BTA)

Bimetallic Sensor

Manual Generators

GTN-25 & GTN-20 Magnets

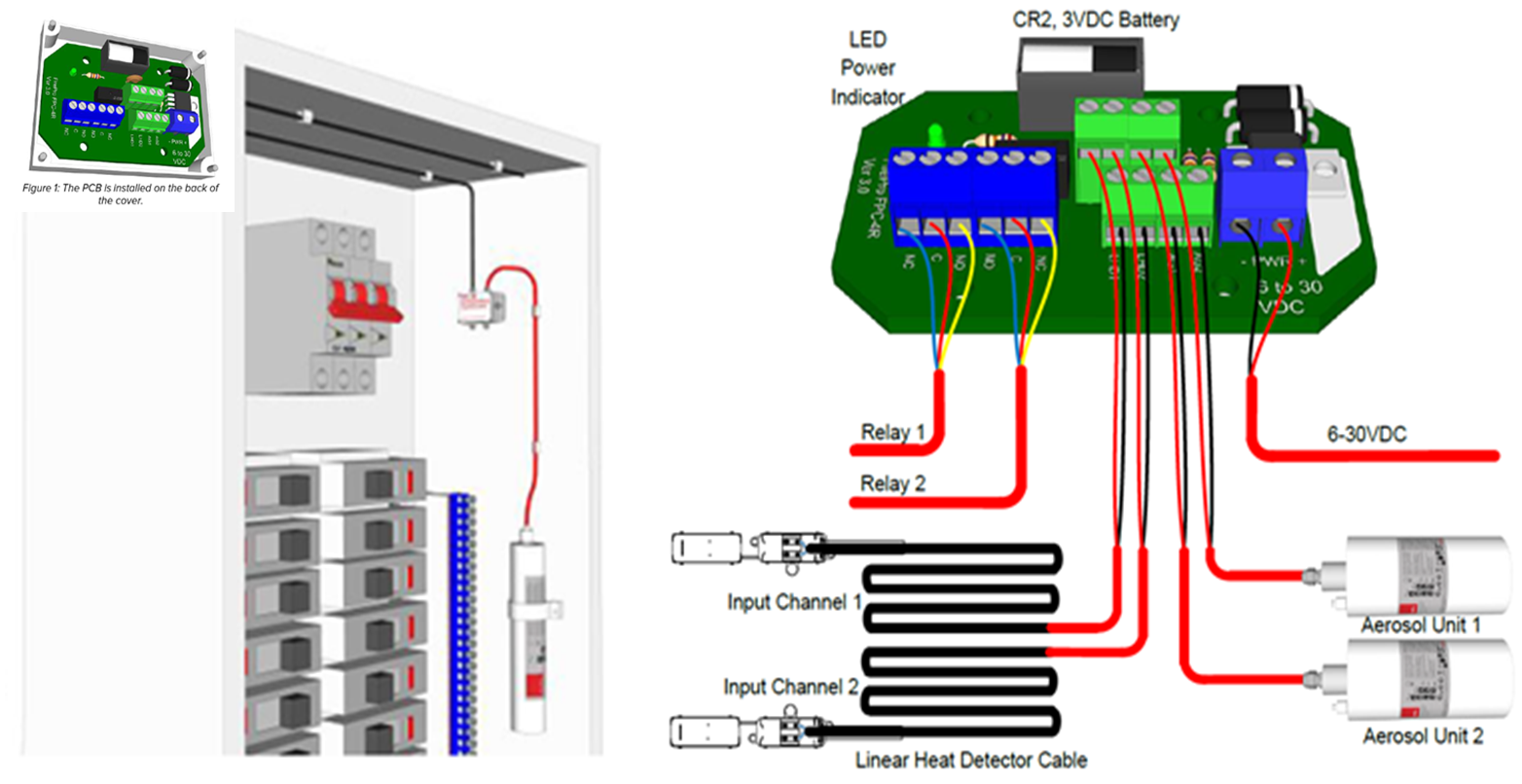

FPC4 – v3

Description

3V battery (sec. source) and externally uses any DC. |

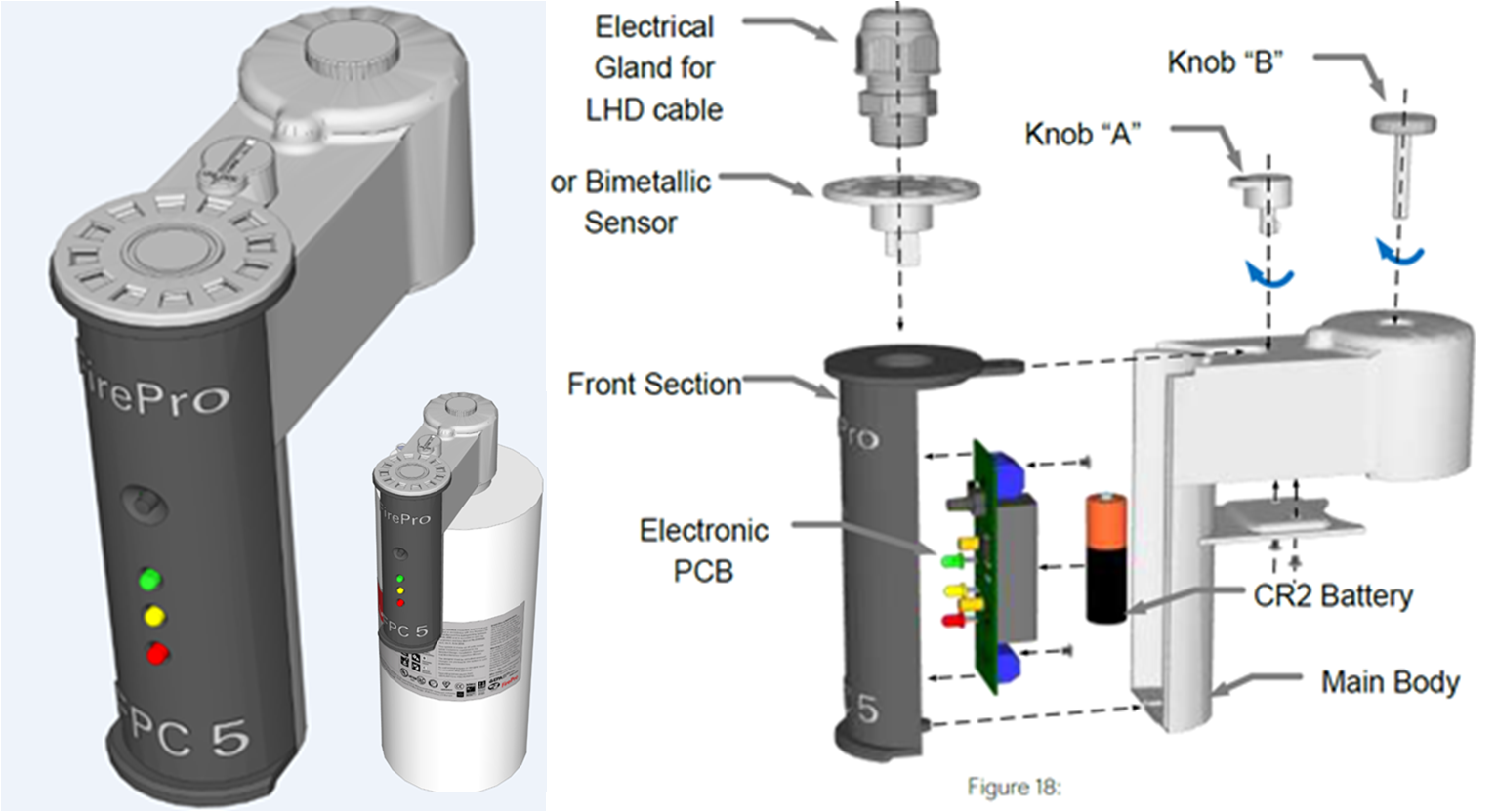

New FPC5

Description

of the unit (Green, yellow, red), indicating battery condition . |

LPS (LEAKAGE PREVENTION SYSTEM)

Description

Declaration of Conformity based on the test requirements of ISO15779:2011. The declaration mentions that 0.17% is the maximum leakage area to volume ratio for ensuring the 10-minutes minimum hold time (as required by ISO, NFPA & CEN standards).

| No. | Leakage Area to Enclosure Volume Ration |

Additional density (g/m3) |

Time to release the additional density |

|---|---|---|---|

| 1 | < 0.17% | 0% | NA |

| 2 | 0.171% -0.474% |

30% | 4 min after first release |

| 3 | 0.475% -1% |

50% | 2 min after first release |

| 4 | > 1% | NA | NA |

ATM EXPLOSION PROTECTION SYSTEM

Description

Gas is pumped into ATM and detonated by hand

| Action |

|---|

INTERNATIONAL STANDARDS FOR CONDENSED AEROSOL

| No. | Certificate | Certificate No. | County |

|---|---|---|---|

| 1. | KIWA | BRL-K23001/04 | NETHERLANDS |

| 2. | ISO | 15779:2011 | INTERNATIONAL |

| 3. | CEN | TR15276-1/2, 2009 | EUROPE |

| 4. | UL | UL-2775 | UNITED STATES |

| 5. | NFPA | NFPA-2010 | UNITED STATES |

| 6. | BSI | KM 547633 | UNITED KINGDOM |

| 7. | IMO | MSC/Circ.1270 | INTERNATION (Marine) |

| 8. | GA | GA499.1,2010 | CHINA |

| 9. | SI | SI 5210 | ISRAEL |

| |

|||||

|---|---|---|---|---|---|

| Power Stations | Industrial | Telecoms | Railway | Marine (incl. Oil Rigs) | Hospitals |

| Mining | Military | Storage - Warehouses | Electrical Rooms | Electrical Panels | Battery Rooms |

| Patch panels | Radars | Wind turbines | Cable ways / tunnels | Motors / equipment | Vehicles |