- Expert Since 2013

- +918347947404

- ashaenterprise123@gmail.com

Wind Turbine Fire Suppression SYSTEM

WIND TURBINE FIRE SYSTEM

The Risk: Catastrophic Fires in Remote location Wind Turbines

Automatic fire protection of wind turbines is of great importance as the consequential damages of wind turbine fires is enormous. This risk has gained considerable attention as the number of wind turbines multiplies worldwide.

Our fire suppression systems for protecting wind turbines are built to a simple design, which uses pneumatics in preference to electronics. This reduces the need for any separate backups using batteries or alternative power supplies and helps to make the system robust and reliable.

With electrically-operated equipment, it is essential to choose non-conductive extinguishing agents which will not damage sensitive components or leave behind any residue.

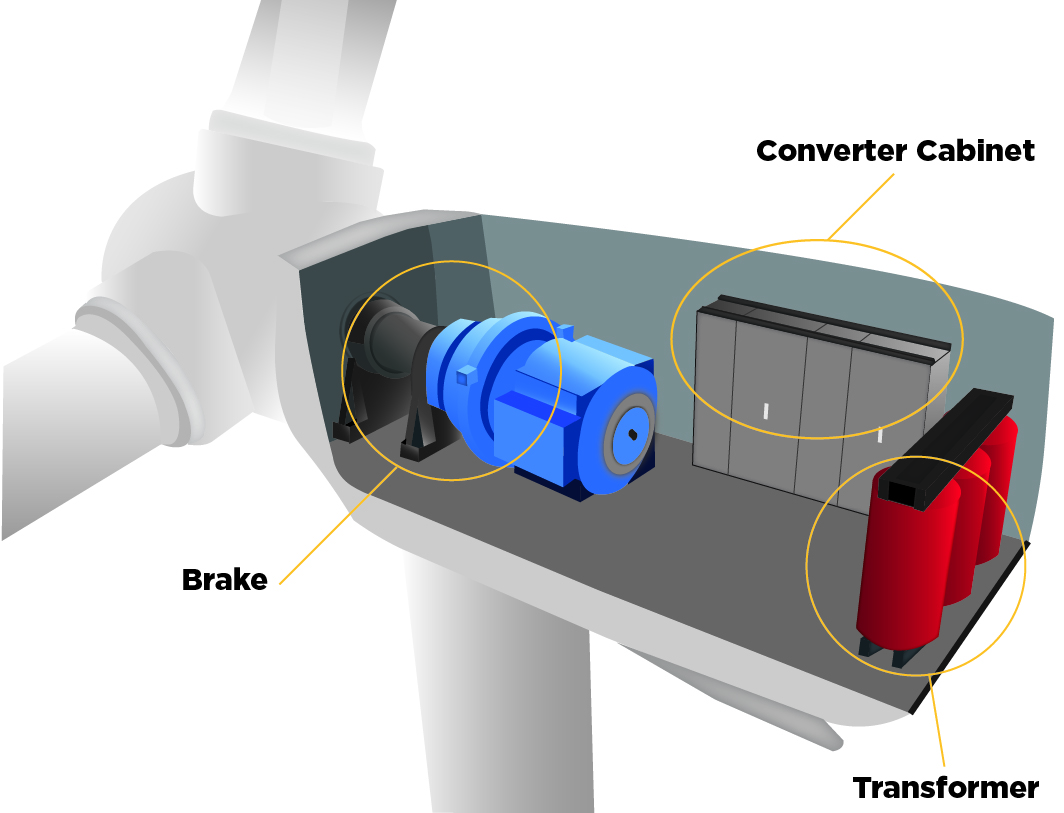

Asha can install various extinguishants which fit this requirement, including Novec 1230, hfc-227-ea , FM 200 , the most eco-friendly product of its type on the market, which is also non-toxic. Fire provides the second highest risk of damage to wind turbines after blade failure. A fire can spark because of mechanical failure, electrical malfunction, or a lightning strike. These sparks can ignite flammable materials inside the nacelle such as resin, fiberglass, or insulation contaminated with oil deposits. Electrical fires in wind turbines can result from shorts in equipment and surges from lightning strikes. Secondary wind-driven brush fires can also result in additional damage.

CAUSES OF FIRE

Lightning strikes - Electrical malfunction - Mechanical failure - Errors with maintenance. Highly flammable materials such as hydraulic oil & plastic near machinery and electrical wires can overheat and ignite. Winds can fan fire inside the turbine. Fires will impact energy production and economic output

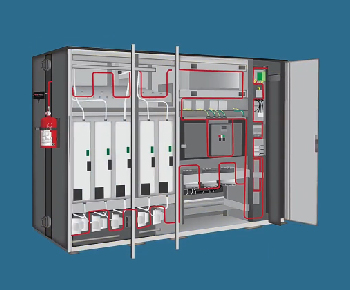

At-risk areas to be protected by STANDARD GASES

- Controller

- Converter

- Switching System

- Braking System

- Generator

- Transformer

TYPES OF FIRE SUPPRESSION SYSTEMS

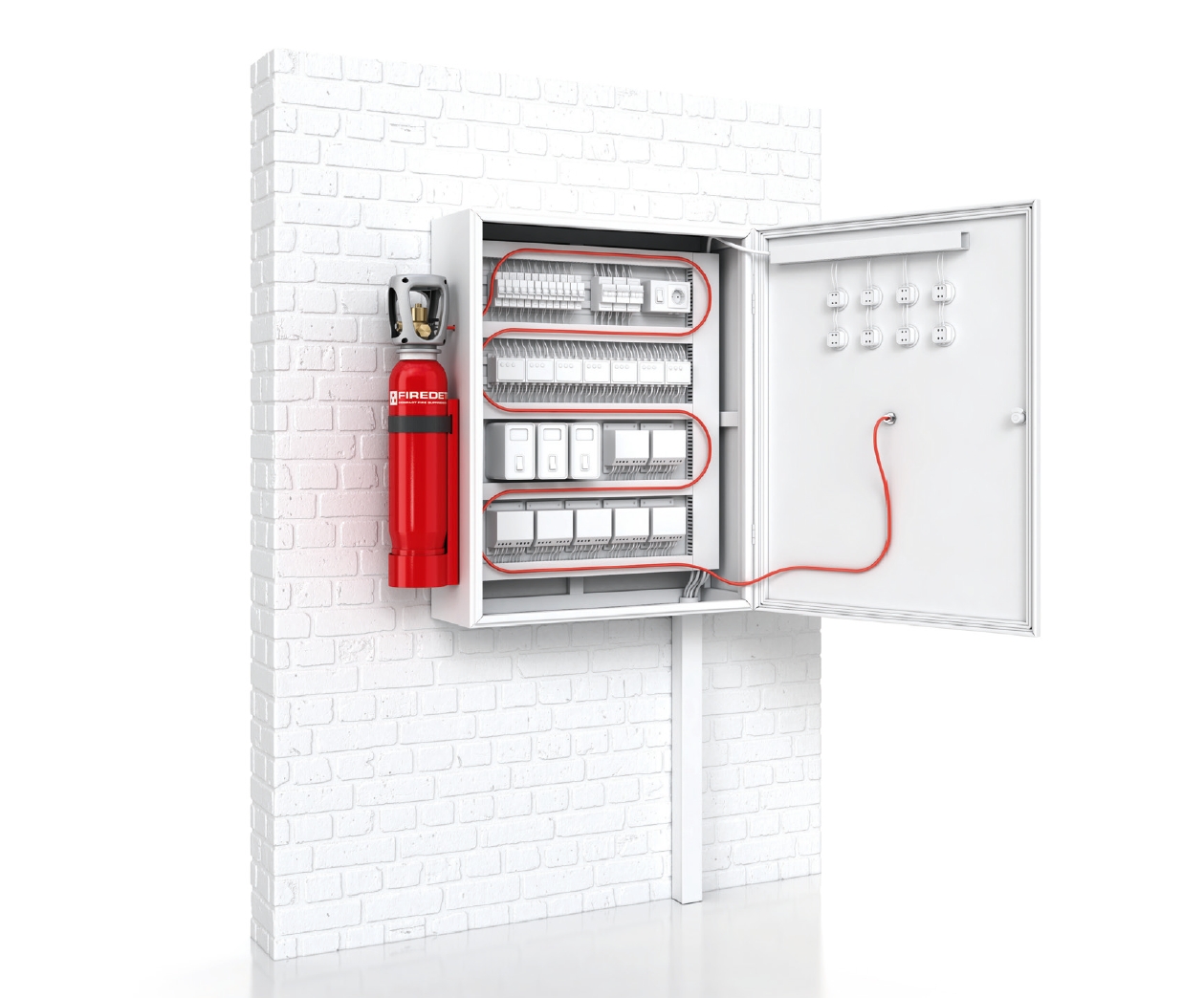

This system is referred to as indirect, which means that it is activated by disruption of the detection tube and the agent is distributed via separate distribution tubes to the nozzles.

The fire suppression system operates by detecting heat with a detection tube connected to the valve of the cylinder. The tube is placed in the protected enclosure and is under constant pressure, whereby keeping the valve piston of the cylinder closed. The indirect system is suitable for larger environments or where specific application of the agent is required. This system also enables various modifications by adding optional components such as manual actuation, control panels for enhanced operation and control of the system.

Automatic fire suppression systems using clean agents, like Chemours FM-200 and 3M Novec 1230, are an ideal option to protect wind turbines.

Little space is required for cylinders that contain the clean agent, detection tubing is easily routed around the specific areas within the wind turbine you are trying to protect, and the systems do not require electricity to operate.

The systems are less prone to false activation, and clean agents are safe in occupied/confined spaces around people and do not damage equipment.No residue is left after a discharge of the clean agents; therefore, no clean-up is required. Completing annual inspections will ensure the systems are in proper working order.

The challenge in using CO2 systems is the need for an airtight nacelle, which is not the case for onshore wind turbines.

When activated in an airtight environment, these systems provide suppression within seconds after discharge and can penetrate inside components and equipment.

When activated in an airtight environment, these systems provide suppression within seconds after discharge and can penetrate inside components and equipment. The maintenance of gas-based systems is rather low and should be checked or monitored for the level of CO2 to ensure no leaks.The The cylinder's master valve is electronically operated and the slave valve is sure actuated.